Mena3D GmbH Baeckergasse 41, 93059 Regensburg, Germany

Phone: +49 941 5699 8278

E-mail: info@mena3d.com

General Manager: Dr. Khaled El Nabbout

Registr.no.: HRB 20490 VAT: DE290789199

Responsible for content: Mena3D GmbH

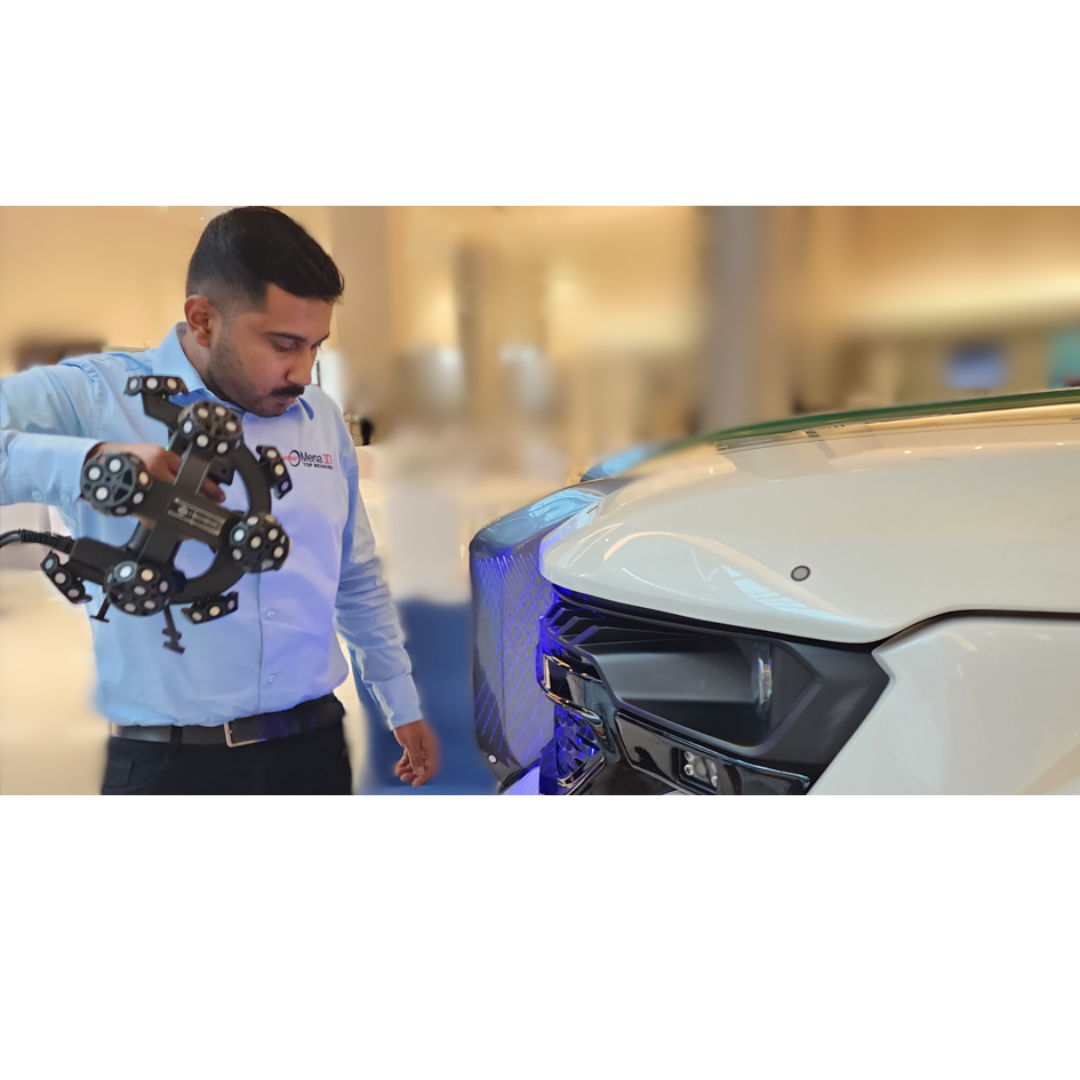

Mena3D marketing materials are based on Mena3d employees and partners