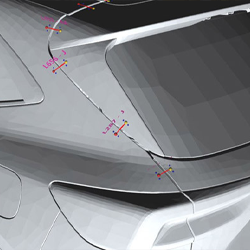

Gap and flush inspection between assembled automotive doors and bodies is a critical factor in modeling a car's aerodynamic performance and, in turn, determine its fuel efficiency. The handheld K-Scan MMDx laser scanner is an effective solution because it digitizes the complete spine in between hood and front fender, for example. A color-coded visual inspection reports graphically illustrates how flush & gap evolves along complete spine. The Cross scanner is the best-suited probe for automotive gap and flush inspection. With multiple lasers sweeping simultaneously, no reorientation of the probe is required to measure this complex and crucial geometry. A single scan path can be defined to follow the 3D curvature of the gap, and the cross scanner will automatically collect the data.